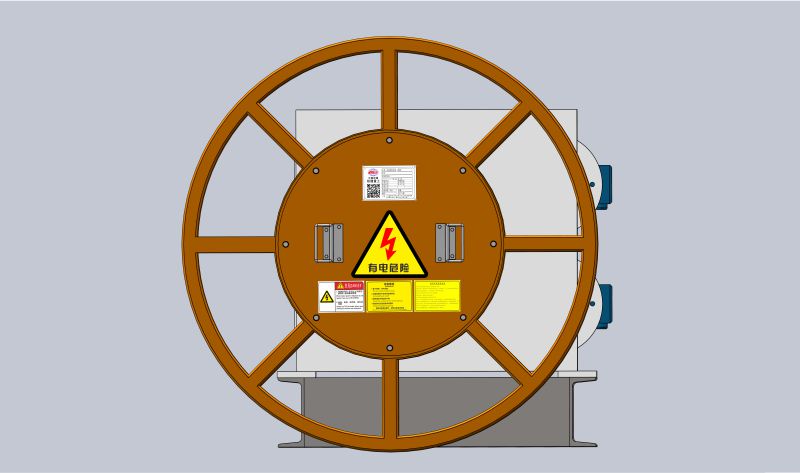

LTMCR Long-term Stalling Torque Type Cable Drum

Overview: Due to the simple structure, LTMCR long-term stalling torque motor type cable drums are especially applicable to severe environments, including workplaces with great dust content in the air, such as mines, cement plants and steel plants. Structural characteristics of long-term stalling torque motor type cable drum:1. The host integrates a long-term stalling torque motor, a special reduction gearbox and a collector slip ring box.1) Characteristics of long-term stalling torque motor:a. The cable tension is constant from empty reel to full reel. It is applicable to long-term low-speed conditions with frequent reversions.b. Low stalling current, enabling long-term stalling and reversed rotation.c. Before assembly, it has gone through 8~10h stalling test, and the motor temperature rise <65K. Under the thermal state, the drop of stalling torque is within 5%.d. Working principle of brake: When the magnet exciting coil of brake connects to the rated voltage (DC), it attracts armature with electromagnetic force to detach (release) the armature from the brake disc. At this time, the motor shaft will drive the brake disc to start normal operation. When the motor is powered off, the brake will also lose power. In such situation, the spring will press against the armature and force the brake disc to produce friction torque with the armature and the flange disc to quickly stop the motor shaft from rotating.2. The collector slip ring box is the power (signal) transmission part. It can be divided into power transmission and signal transmission by the purpose, or 500V, 3KV, 6KV, 10KV and 20KV by the voltage level.

3. Cable storage part: The reel is the cable storage part and be can be divided into multi-row winding and single-row winding. To facilitate transportation, reels with a diameter ≤2.6m are of an integral structure while those >2.6m are of two semicircular structures to be assembled by the user on the site.4. Electrical schematic diagram of cable drum: Electrical schematic diagram of cable drum.Working principle of cable drum:The power part and speed adjustment part on the long-term stalling torque motor type cable drum are undertaken by the motor. Such motor has unique electrical and mechanical characteristics. The motor has a wide range of speed regulation and soft mechanical characteristics. When meeting load changes, the motor's operating rotational speed will change corresponding. Specifically, when the load increases, the rotational speed decreases; when the load decreases, the rotational speed increases. Besides, the motor can enable long-term stable operation at any point on the mechanical characteristic curve of its torque and rotational speed, thus can assure the cable could acquire proper winding speed and tension on the corresponding radius of the reel. Please be aware that the driving motor of the cable drum is power-on even during cable release, and the phase sequence is the same as the cable collection direction.1. Cable release: When the motor is power-on, the motor output torque is hinder strength, preventing the cable from being pulled out of the reel too quickly and guaranteeing the synchronization of cable release.2. Cable winding: When the motor is power-on, the motor output torque is power and drives the reel to collect the cable through the reduction part.3. During shutdown: The long-term stalling motor has a normally closed brake to ensure the cable will not slip off the reel under the action of gravity when the motor is power-off.

- The key role of cable reel in industrial development and the way to solve customer pain points

- Shaping the future: Market change and user demand evolution of smart cable reels

- The future development of the cable drum market: Vigorous growth led by technological innovation and intelligence

- Yueyang Kailixin Electric Co., LTD. : Excellent choice in the field of cable reels

- The utility of cable reel in industry and life

- The key role of cable reel in improving power supply efficiency and saving cost

- Advantages of cable reels in construction vehicles, ports and mining

- Decoding cable reels: Environmental challenges, application diversity, and future application prospects

- In-depth Understanding of cable reels: Industry applications and technological innovation

- The Global Market for cable reels: Development, Innovation and the Future

- Cable reel: Mechanical, electric or pneumatic, which is better?

- How big is the future market for cable reels? The market size is very optimistic!

- How many stages has the development of cable drums gone through so far? What is the future development direction?

- How many types of cable reel are there? Cable drum detailed science!

- How to protect cables? Extending the service life of cables?

- Why are engineering vehicles so fond of cable reels? The effect is obvious!

- What is a cable reel? What will be the future development?

- Why is the spring-type cable reel sought after by many manufacturers?