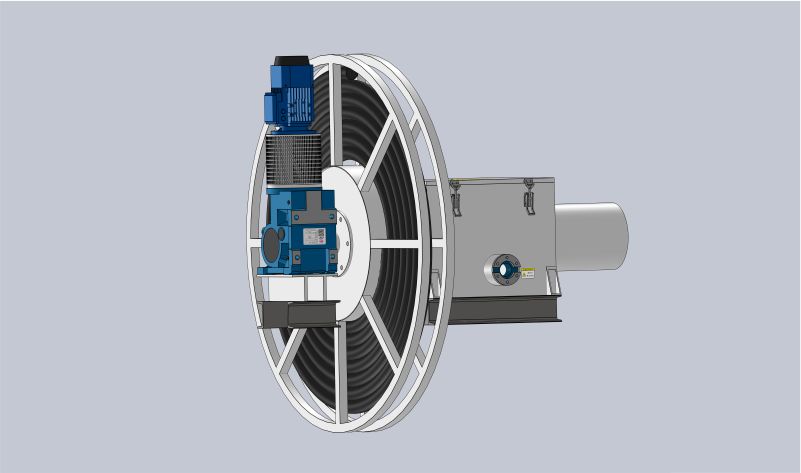

MCCR Hysteresis Type Cable Drum

Overview: MCCR hysteresis cable drums are widely applied to port machinery, bulk yard machinery, large-scale lifting appliances, hydraulic machinery, engineering machinery and other large-scale machinery that requires parallel translation. They utilize the cable winding and release of cable drum to transmit power source and control signals and apply to workplaces like ports, power plants, bulk yards and hydro-junctions.

Structural characteristics of hysteresis type cable drum:1. Host: The host integrates a reduction gearbox, a power head and a collector slip ring box. The power head consists of a motor, a hysteresis coupling and an epicyclic gearbox. Based on the operation conditions, single power head or multiple power heads may be adopted as the drive power of hysteresis cable drum. The collector slip ring box is the power (signal) transmission part. It can be divided into power transmission and signal transmission by the purpose, or 500V, 3KV, 6KV, 10KV and 20KV by the voltage level.

2. Cable storage part: The reel is the cable storage part and be can be divided into multi-row winding and single-row winding. To facilitate transportation, reels with a diameter ≤2.6m are of an integral structure while those >2.6m are of two semicircular structures to be assembled by the user on the site.3. Working principle of hysteresis coupling: Hysteresis coupling adopts magnetic principles to combine the driving magnetic half and the driven magnetic half into a pair of magnetic parts to realize magnetic non-contact coupling through magnetic force and achieve torque transmission. One magnetic half is a magnetic disc composed of permanent multipolar magnet steel. The other magnetic half is a high-intensity induction disc. When the motor drags one of the magnetic halves for high-speed rotation, once there is a speed slip frequency difference between the two discs, the multipolar magnetic disc will alternately magnetize the opposite induction disc and produce a torque that resists this slip frequency difference, also known as the non-contact magnetic coupling between the two discs, to realize dragging (or braking) the discs for rotation. When the air gap between the magnetic halves is adjusted, the damping torque will be adjusted. When the air gap distance is locked, the damping torque can maintain constant during operation and will not change as the relative speed of the change of driving and driven halves. Since the hysteresis coupling is capable of the special function of torque coupling and realizes constant torque, the cable drum can achieve the ideal winding features and become the most suitable device for cable collection and winding.

Working principle of hysteresis type cable drum: The motor of the cable drum transfers the power to the hysteresis coupling. After the speed regulation and slip frequency difference of the hysteresis coupling, a stable constant torque can be acquired. After speed reduction, the enlarged torque can be transmitted to the cable drum. Please be aware that the driving motor of the cable drum is power-on even during cable release, and the phase sequence is the same as the cable collection direction.1. Cable release: It resists the torque of magnetic field of the hysteresis coupling through dragging the cable. A slip frequency difference will produce between the two discs and release the cable on the reel. At this time, the motor is power-on.2. Cable winding: When the lifting equipment returns, the drag force on the cable eliminates, and the cable drum rotates in the set winding direction to realize cable coiling.3. During shutdown: Each motor has a one-way bearing on the output shaft or simply a brake to ensure the motor would have sufficient brake torque when the motor is power-off, so the cable won't slip off the reel under the action of gravity.

- The key role of cable reel in industrial development and the way to solve customer pain points

- Shaping the future: Market change and user demand evolution of smart cable reels

- The future development of the cable drum market: Vigorous growth led by technological innovation and intelligence

- Yueyang Kailixin Electric Co., LTD. : Excellent choice in the field of cable reels

- The utility of cable reel in industry and life

- The key role of cable reel in improving power supply efficiency and saving cost

- Advantages of cable reels in construction vehicles, ports and mining

- Decoding cable reels: Environmental challenges, application diversity, and future application prospects

- In-depth Understanding of cable reels: Industry applications and technological innovation

- The Global Market for cable reels: Development, Innovation and the Future

- Cable reel: Mechanical, electric or pneumatic, which is better?

- How big is the future market for cable reels? The market size is very optimistic!

- How many stages has the development of cable drums gone through so far? What is the future development direction?

- How many types of cable reel are there? Cable drum detailed science!

- How to protect cables? Extending the service life of cables?

- Why are engineering vehicles so fond of cable reels? The effect is obvious!

- What is a cable reel? What will be the future development?

- Why is the spring-type cable reel sought after by many manufacturers?